If you are new to simulation or probably don’t know that much about it, then you might be wondering “why is it so important”?

Well, that’s what we are going to cover here! Please note that simulation is nothing new! it has been here since the existence of computers but of course they have been adjusting to the needs of the engineer. I’m confident that one day will arrive in which the same AI of the software will eventually substitute several Process Engineer tasks, if not all of them!

Process Simulation Advantages

- Saves TIME!

- Saves human error!

- Gets better designs

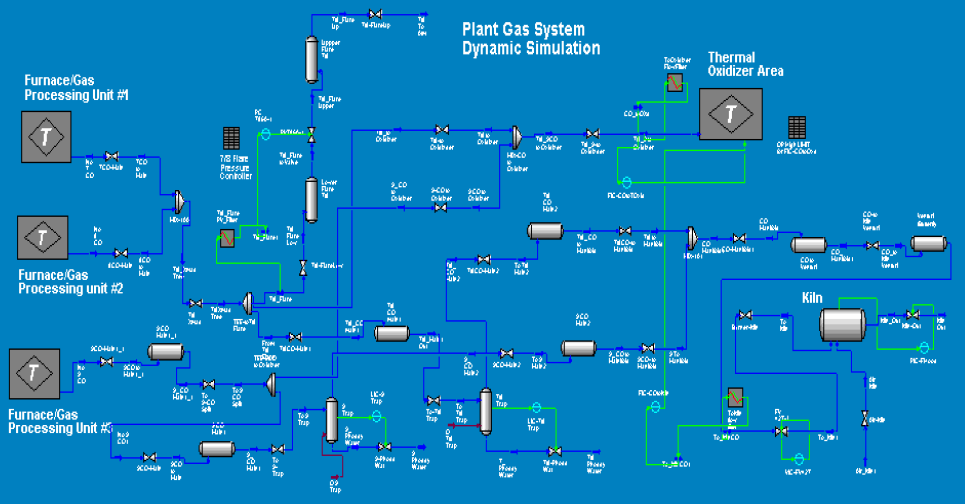

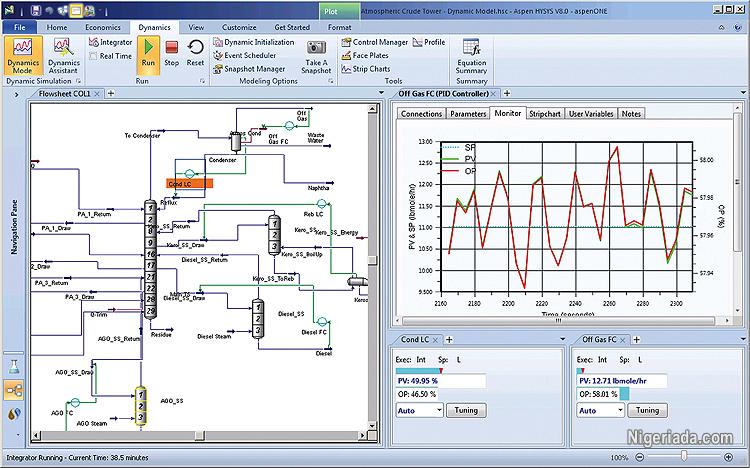

- Let us picture the process: size, types, dimensions, duties, utilities, costs, etc…

- Can be used for “what-if” scenarios

Process Simulation Disadvantages

- Will always depend on final decision of the engineer

- It will never be 100% accurate

- it bases in several models, iterations and numerical data which can stil have error within

- Process Simulation is not a GOAL but rather a tool to achieve another GOAL

- Will still account for RISKS

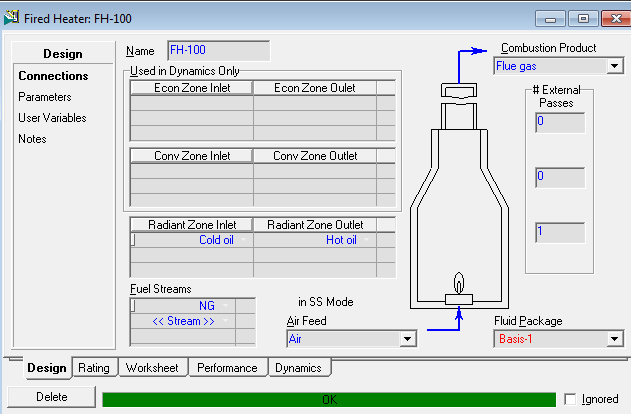

Typical things we model...

When modeling, the engineer is likely to model the following:

- Thermodynamic Modeling of pure substance or mixture of substances

- Transport Property modeling

- Model of crude oils, physical properties, chemical and their respective cuts

- Equipment sizing, performance and costs

- Process conditions

- Mass flow rates & compositions, purities, and specification compliance

- Energy and Material balances

- Heat and Cooling Duties as well as Compressor/Pumping requirements

- Health Risk and Hazard Analysis

- Economic analysis (costs, price, sensitivity, profit, etc)

- Technical feasibility

- Optimization with constraints

- What if scenarios, sensitivity of the process

Wrap-up

Process Simulation is powerful as it will allow us to save a ton of time, money, resources and even human lives.

It allows us to open a new panorama, as now our imagination is not the limit, rather what we input/output in the process simulator, we can test multiple case studies in order to verify the best case or the optimal condition.

Process Simulation is also a position which is regarded with high respect and keeps growing as time passes by. The final task of the engineer will be to ensure good practice in the simulations, and, THANK GOD, will always be the one taking the FINAL DECISION.

Have you tried Process Simulation before? What type of software? How long?

Please let us know down below in the comment section!